Slip rings are mainly used in any electromechanical system that would require rotation during the time of transmitting power or even transmitting signals. It will not only improve the mechanical performance or simplifies the system operation but it also eliminates the damage-prone wires which dangle from the movable joints. A slip ring is really a technique of constructing an associate electrical association through a rotating assembly. When it comes to getting slip rings, then you can find the best slip ring manufacturers and go according to that.

What exactly is the function of slip rings?

As the slip rings make continuous electrical connection between stationary and moving conductors, it enables the stationary power source in order to transmit the electrical power towards the rotating component. It is basically a band of electrically conductive material which is mounted on a shaft. Well, Slip rings are used to offer the Direct Current excitation to the rotor of respective Alternator.

When it comes to Direct Current supply, it is mainly starting to get generated after the rectification of the alternator output that is stationary. However, the rotor is supposed to be fed with electricity or is in a rotatory motion. We may think of it as follows that the slip ring and brush arrangement as an interface between the rotating rotor and the stationery Direct Current supply.

Things to know about wind turbine

A wind turbine is a device that helps to convert the kinetic energy from wind into electricity. The blades of the wind turbine are made to turn at the speed of around 13 to 20 revolutions per minute, depending upon the technology. Then, they are getting a chance to turn at a constant variable velocity. Well, the rotor velocity is mainly varied in terms of relation to the velocity of the wind.

This enables greater efficiency in the functioning of the wind turbine. It is essential to know that the wind turbine is automatically oriented in order to take kinetic energy’s maximum advantage of the wind and start to work with great efficiency.

The data register enables this by the vane and the anemometer that is mainly installed at the top of the turbine. The blades are then made to turn at the speed of 3.5m per second. When it comes to high-speed winds which are an extreme state, then the blades are feathered as well as the wind turbine starts to slow down to prevent excessive voltages. The gearbox is used to transfer its energy through a fast axis that is connected to the generator, which ultimately produces electricity.

How are slip rings used in wind turbines?

A newsletter called the Windpower Newsletter that mainly explains it best as to how the technicality of the slip ring and the turbine actually fits in. This newsletter is meant for reviews of electrical devices which generate power through the use of wind as a source of kinetic energy.

It applies to all the products that are manufactured by or are in association with the company ‘Wind Power’. The following is its explanation of how slip rings aid in the functioning of wind turbines, A slip ring can provide reliable transmission of power and signals from stationary cables within the enclosure to rotating instrumentality within the hub.

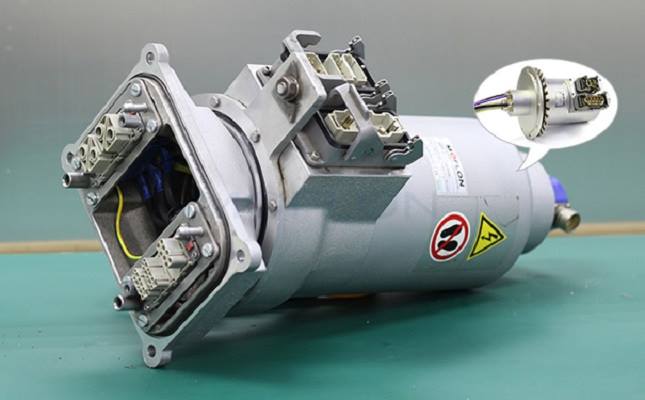

A mistake ring assembly is commonly a solid metal or precious-metal wire brush that contacts the surface diameter of a rotating metal ring. Because the ring turns, electrical current or signal conducts through the comb to the metal ring creating the association.

The wind-turbine service market is growing hugely because the rotary engine population ages and plus house owners are trying to find ways that to regulate maintenance prices and maximize rotary engine convenience and output. For information, new solutions are required to exchange older technology slip rings in turbines with long, high-reliability styles which will operate for years while not maintenance. An ideal pitch connection would be put in and forgotten.

Replacing the complete connection comes at intervals that are thought of short. Whereas OEMs are pushed to lower-cost parts, operators are pushed to include merchandise that cut back the necessity for technicians to be within the turbines. Keeping the rotary engine technicians out of the enclosure can keep prices down and outputs up.

Power transmits as one load whereas an integral data-communications system switches power, as an example, to satisfy totally different device necessities of wireless receivers. During this method, the slip rings offer wireless power and knowledge to pitch management in wind turbines, up potency by reducing the price of maintaining and substitution existing mechanical slip rings and their carbon brushes. Any size rotary engine is often supported as most of the corporate are claiming it.

Use of specially designed high-reliability slip rings

UK based group, Moog Components Group Limited, has introduced a new pitch control slip ring which seems to be very promising as it is considered the next generation of advanced connection merchandise specifically developed for the wind energy market. Its specialty is such that it offers a longer range of average life at a lower cost to the customers. Moreover, it is more efficient than most slip rings prevalent in the market and is, therefore, providing a tight competition to its peers and contemporaries.

Moreover, not only is it useful for the wind turbines but it can also be used in other industrial machinery and equipment. It has sought to revolutionize the working procedure of the common slip rings by providing unprecedented efficiency in its performance where energy lost due to friction is minimized.

Conclusion

For a long time, if you are struggling to know more about wind turbine slip rings, then this research only discusses wind turbine slip rings and there is much good fact about it which describes many things about it. Research tells that part of it which only a few people know so get more and enjoys learning. At the end of the day, this discussion will offer you a lot to gather.